The Advantages of Applying 3D Printing

3D printing has a lot of benefits that you cannot get from the traditional methods of prototyping, whether you are doing it at a local, personal or industrial level. Customization is one of the benefits of 3D printing. This kind of printing will allow you to enjoy mass customization, which deals with the personalization of products to fit an individuals requirements and needs. Printing in three dimension means that many products can be manufactured simultaneously according to the requirements of the end user without any additional costs.

The waste that is being produced by 3D printing is minimal. The process of manufacturing plastic and metal objects has always been wasteful, involving a lot of extra material and chunky parts. There are aircraft makers who would cut away and dispose around 90 percent of the material. With 3d printing, less energy is being used and waste is being reduced to a minimums. There are times when the finished products are 60 percent lighter in comparison to the machine parts. The impact on the surroundings or environment is less because of production of less waste.

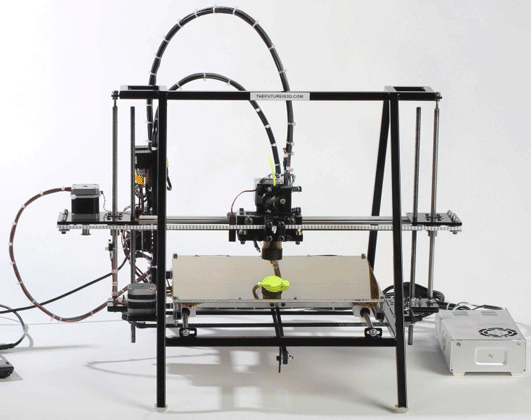

You are more than likely to get better quality products when you use 3D printing. Printing in three dimension allows manufacturers to avoid the faults that come with mass manufacturing. It extends the life of products as they will not break often. This is, however, not beneficial to manufacturers who want profitable product life cycles. It is the end consumer who benefits from this. Printing is being used in different sectors due to its accessibility. Check out https://www.youtube.com/watch?v=8aghzpO_UZE for a video that explains 3D printers.

3D printing is giving way to new structures and shapes. Traditional methods of manufacturing rely on cutting and moulding technologies for the production of finite structures and shapes. These might have complex shapes that could have been created by assembling many parts together. This is not the case with printing. The nozzle of a 3D printer can build infinite complex figures. This translates to higher structural integrity and durability. Printing comes with endless opportunities, and one can create jewelry, unique furniture, medical implants and aerodynamic parts.

The combination of different raw material is possible in 3D printing, which one cannot do with traditional methods due to the high costs. In addition, it is harder to combine materials through the traditional methods because of their chemical and physical properties. Many boundaries have been removed by printing in manufacturing because of enthusiasts who continue fueling continuous innovation claiming additive manufacturing is yet to reach its potential.

These benefits of 3D printing are seeing this technology being used in different industries, from those of personal entertainment uses to applications in life-saving fields.